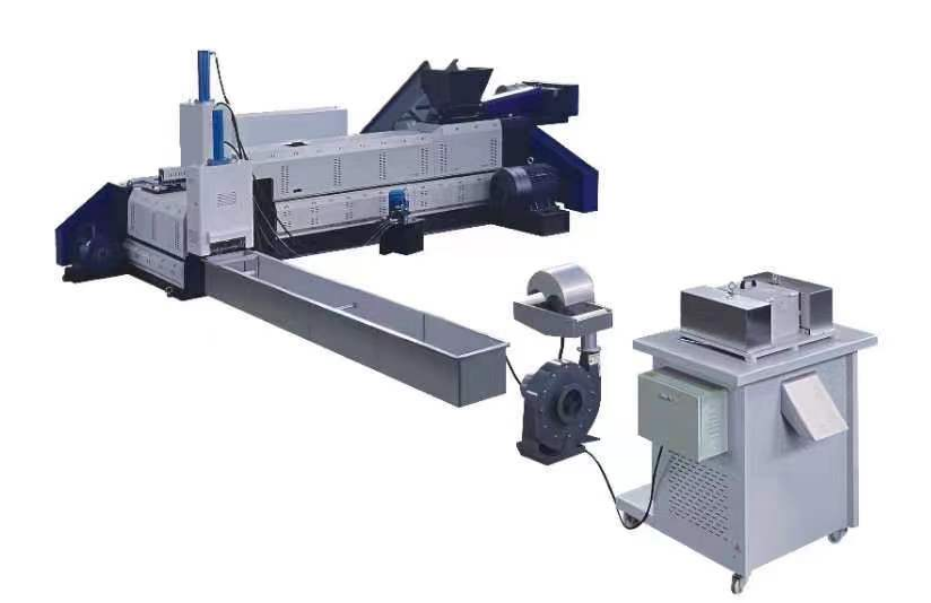

SJ-C200-180 PP/PE Fully High Speed Double Stage Water Cooling Granulator with 400-500kg/hour

1.Feature:

1).This machine suitable for PE, PP waste film recycle, and then granulator int granules;

2).Machine with safety shield, more safety operate and temperature more stable;

3).Finished granule can mix with new material use, it can save factory cost.

4).The feeding adopts an eight claw forced feeding device, greatly improving the feeding speed.

Main Technical Variables:

| Model | SJ-C200/180 Fully Two Stage Water Cooling Granulator |

| Type Diameter of Screw Stem | Φ200mm with SACM-645/38 CRMOALA material |

| Main extruder | |

| Screw&barrel | 200mm |

| Major Diameter Ratio of Screw Stem | 1:22 |

| Main motor | 330 hardness gear reduction box |

| Main Motor Power | 110kw with inverter control |

| Type Diameter of Screw Stem | Φ200mm with SACM-645/38 CRMOALA material polished with Niterided Treatment hardness of heat treatment: screw HV≥740, barrel HV≥900,depth:0.6-07mm |

| Heating zone | 10zoncs on screw&barrel with ceramic heating and 4zone on die head with stainless steel heating |

| With hydraulic pressure non-stop screen changer with 250*250 | |

| Second extruder | |

| Screw&barrel | 180mm |

| Major Diameter Ratio of Screw Stem | L/D 10:1 |

| Main motor | 225 hardness gear reduction box |

| Main Motor Power | 30kw with inverter control |

| Type Diameter of Screw Stem | Φ180mm with SACM-645/38 CRMOALA material polished with Niterided Treatment hardness of heat treatment: screw HV≥740, barrel HV≥900,depth:0.6-07mm |

| Heating zone | 4zoncs on screw&barrel and 2zone on die head with stainless steel heating |

| With hydraulic pressure screen changer with 250 | |

| With 5.5kw motor cutter with 18pcs rotating knives&1pcs fixed knife | |

| With stainless steel tank for granules (1ton capacity) | |

| With automatic conveyor with auto-brake function (belt size:600*4500mm W*L) | |

| Output | 400-500kg/hr |

| Weight | 8500kg |

| Dimension | 10.5×7.8×2.5m |

| Power supply: | 380V 50HZ |