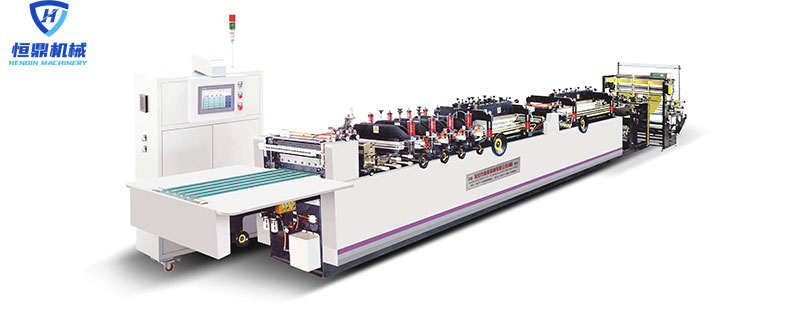

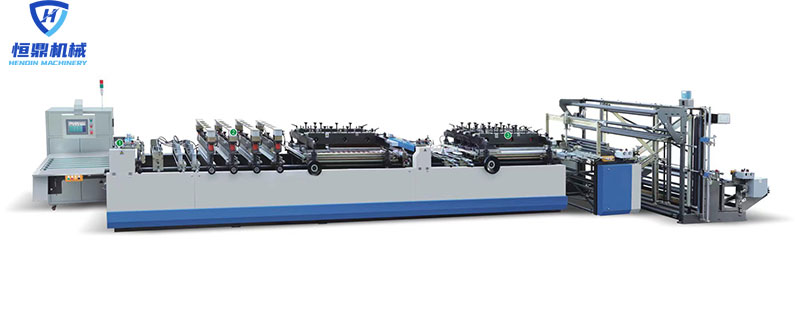

HD-ZUC400/500/600 FOUR SIDE SEALING&MIDDLE SIDE SEALING POUCH MAKING MACHINE

PERFORMANCE AND CHARACTERISTICS

- Whole machine controlled by centralPLC control system with man-machine. More stable performance.easy for oreration and maintenance. Chinese and English interface language can be shifted easily.

- Constant auto-tension control for unwinding,LPCedgealignment,ACinverter constantspeedautomaterialfeeding

- Imported double servo-motor material dragging contral system

- Main motor for up-down sealing and pressing equipped with inverter.

- PID for sealing bar temperature adjustment,notouchautocontrol,centralized setting in man-machine interface,

- Equipped with Pneumatic multi-functionautopunchingdevice,trimcuttingand auto rewinding and static eliminator

- Temperature adjustment range:0~300℃

- Counter:quantity,batch accumulation,pre-set available.

- Operation Method:by length fixation control and/or by photocell tracking control. 10.Punching device:working rhythm can pre-set as continuous,interval or stop, punching time can be pre-set.

- Material Skip Feeding:one to six times available.

- Batch Conveying Function available,the quantity of batch can be preset.

Machine specification

| Model | HD-ZUC400 | HD-ZUC500 | HD-ZUC600 |

| Max.diameter of roll material | Φ600 | Φ600 | Φ600 |

| Max.width of roll material | 850mm | 1050mm | 1250mm |

| Max.Speed | 150pcs/min | 150pcs/min | 150pcs/min |

| Material feeding speed | 35m/min | 35m/min | 35m/min |

| Max.bag making width | 400mm | 500mm | 600mm |

| Bag-making length | 50-2400mm | 50-2400mm | 50-2400mm |

| Total power | 25kw | 30kw | 35kw |

| Machine weight | 4500kg | 5000kg | 5500kg |

| Machine dimension | 10550*1700*1830mm | 10500*1800*1830mm | 10500*1900*1830mm |