Introduction

Carton Erecting Machine (Paper Box Forming Machine) is an automatic machine, specialize in making food carton, box, container which are made from cardboard, paper, paperboard, corrugated paper etc.

The food box (carton, container, dish, tray) is widely used as burger box, hot-dog box (tray), one block box, food pail box (Chinese food box, take-away box), fries box (chips box, chips tray), lunch box, meal box, etc.

Advantage

- Compact structure and strong frame keep the machine reliable and durable with low noise.

- Paper Feeder driven independently by servo motor.

- Hard Plastic-glass cover, Safe and visible for user.

- Easy exchange molds to make different products, charging and adjusting time is very short.

- PLC program control the whole line, available to make complicated boxes.

- Automatic collection, stock, and count.

- Human being designed control button and panel, more easy and safe runs by user.

Technical Specification

| Model: | Carton Erecting Machine (Paper box forming machine) | |||

| Speed: | 80~180 box/minute | |||

| Welding Method: | Water-Glue System Welding;

(Food grade glue, POLYVINYL-ACETATE EMULSION), |

|||

| Available Material: | 150~600gsm board, paperboard, paper, film coated paper, etc. | |||

| Material Thickness: | Max. 1.5mm | |||

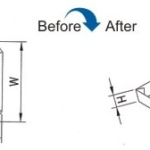

| Paper Size: |  |

L=Length: 60~450mm | ||

| W=Width: 60~580mm | ||||

| H=Height: 10~200mm | ||||

| Angle: 50~300 | ||||

| Power: | 4.5KW, | |||

| Power Source: | 3-phase, 380V, 50/60Hz, | |||

| Machine Size (L*W*H): | 3520*1510*1420 | Pack Size | 3550*1550*1700 | |

| Weight: | 2000KG; | |||

| Air Source: | Pressure: 6KG/cm2 ; (0.6MPa);

Out-put: 200 L/minute ; (0.2~0.4 m3/minute); User Need To Buy Air Compressor |

|||

| Available to make machines and molds on user order. | ||||

Standard Output Capacity

| 4-corner box without cover, Boat Shape Box, Boat Tray, | Max. 180pcs/min; |

| Fries box (chips box, chips tray): | Max. 140pcs/min |

| Burger box, hot-dog box, Lunch box | Max. 120pcs/min |

| Food pail (DEEP food box): | Max. 100pcs/min |

Remark:

- The box size, box shape, material and its quality will affect the machine output.

- While the material is TWO-side FILM coated paper, or aluminum foil paper, should ADD hot melt glue system.

Whole machine include

| # Electric control box; | # Feeding device; |

| # Transfer System: | # Water glue device ; |

| # Forming(welding) device; | # Collection device ; |

| # One set of mold; |

ORDERED BY USER

| # Hot melt glue system; | |

| # Air compressor and dryer . |