Features and Performance

- Material measurement and packaging system consists of bag-feeding packaging machine and unloading system;

- It is convenient and simple to put the bag in the bag slot, and it is equipped with an automatic bag pressing device;

- Equipped with imported pressure sensing device to achieve the effect of no cutting and no sealing, saving packaging bags;

- Giving bag type packaging system, the packaging speed is faster, the weight is more accurate, and the high-quality accessories are used to keep the machine lasting and stable;

- Adopt color touch screen, simple operation, multi-function design;

- The machine adopts the appearance of stainless 304L, and the carbon steel frame part and some accessories are processed with acid-resistant and salt-resistant anti-corrosion treatment.

- Material selection requirements: Most parts are produced by moulding, and the main materials are 304 stainless and alumina.

- A variety of coding, coding, exhausting and punching systems can be selected.

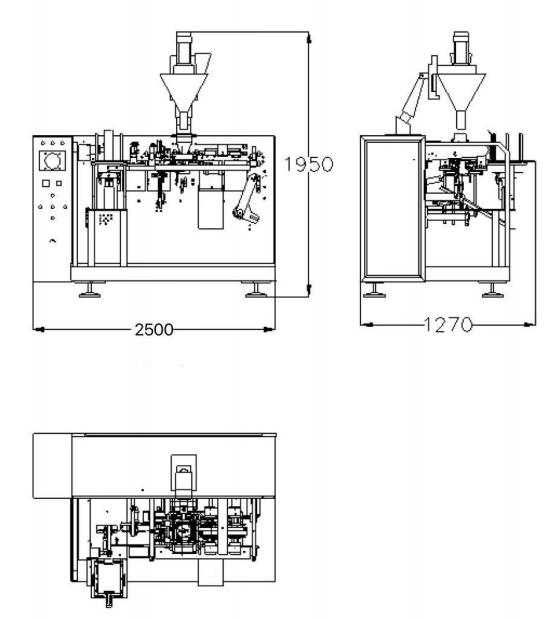

Main machine part¶meter

| Packing Speed | 20-30bags/min |

| Bag size | Width 70-260mm

Length 160-400mm |

| Bag type | Stand-up bag,four sealing bag,zipper bag,paper bag etc. |

| Packing volume | 250g-2kg |

| Total power | 4.5kw |

| Power supply | Single phase 220v |

| Gas consumption | 0.7m3/min |

| Machine weight | 1200kg |

Main electric components

| Item | Electric part | Brand |

| 1 | Programmable controller PLC | Mitsubishi |

| 2 | Color code electric eye | Bradley brand |

| 3 | Monitor | Weilun |

| 4 | buttons | Schneider |

| 5 | Low voltage electric | Schneider |

| 6 | switching power supply | Taiwan Mingwei |

| 7 | Terminals | Feder Miller |

| 8 | Temperature controller | Omron |

| 9 | Servo motor | Schneider |

| 10 | Solid state relay | Schneider |

| 11 | Pneumatic parts | AirTAC |

| 12 | Servo drive | Elis Italy |