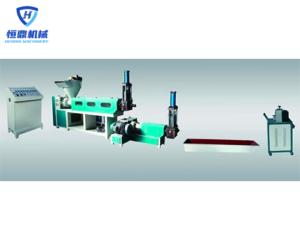

Characteristic

This machine is suitable for regeneration and granulation of waste plastics,as HDPE,LDPE,and PP,etc.It is equipped with quickmotor-operated filter-screen-replacing unit and automatic temperature control.The granulating-crusher uses adjustable speed motor,pelleting with an extruding machine at the same discharging speed synchronistically.The unit is easy to operate,with a high output,steady performance, and favorable economic benefit.

Main Technical Variables

| Model | SJ-B120*110 |

| Type Diameter of Screw Stem | Φ120mm&110mm with 45# medium carbon steel |

| Main extruder | |

| Screw&barrel | 120mm |

| Major Diameter Ratio of Screw Stem | L/D 11:1 |

| Main motor | 400 gear reduction box |

| Main Motor Power | 18.5kw with inverter control |

| Type Diameter of Screw Stem | Φ120mm with 45# medium carbon steel |

| Heating zone | 3zoncs on screw&barrel with ceramic heating and 2zone on die head with stainless steel heating |

| With normal screen changer with 200*200*2 | |

| With exhausting device | |

| Vice extruder | |

| Screw&barrel | 110mm |

| Major Diameter Ratio of Screw Stem | L/D 6:1 |

| Main motor | 350 gear reduction box |

| Main Motor Power | 7.5kw with inverter control |

| Type Diameter of Screw Stem | Φ110mm with 45# medium carbon steel |

| Heating zone | 2zoncs on screw&barrel with stainless steel heating and 1zone on die head with stainless steel heating |

| With normal screen changer with 200*200*2 | |

| Power of cutter | 1.5kw cutter |

| Output | 80kg/h-110kg/h |

| Water cooling baths | 1800*330*330mm |

| Weight of overall(kg) | 3000kg |