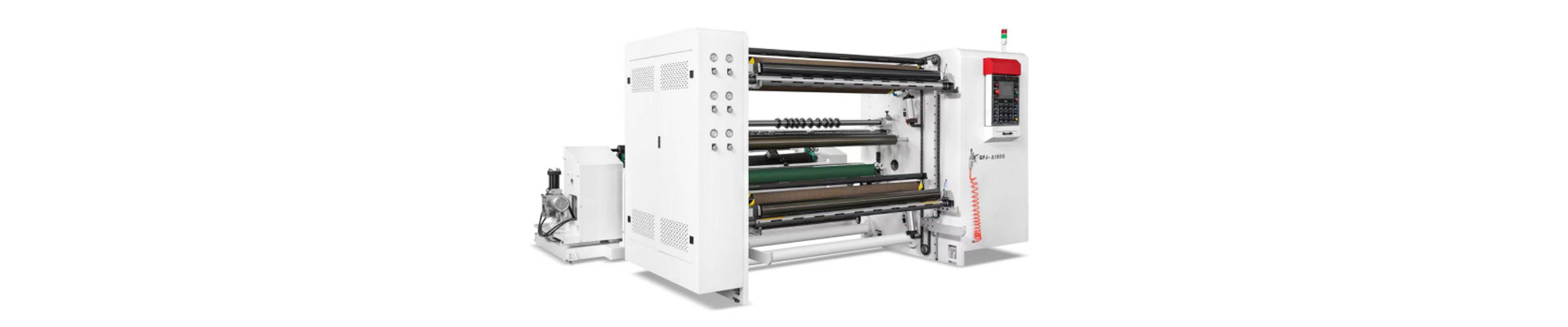

This high speed slitting machine is suitable for slitting roller materials such as BOPP, PET, CPP, CPE, PVC, aluminum foil, adhesive paper, leather paper, and other kinds of paper, etc.

Features

- Use Round Slitting Knife

- With Auto Length Counting System

- Unwind and Rewind with Tension Control

- Unwind with EPC Control System

- Unwind and rewind use Air Shaft

- Inverter use Import Brand

- Electrical Part use Schneider Brand

- Unwind Shaft Type Auto Loading

- 4Motor Drive Tension System

- Optional: Unwind Shaft-less with Auto Loading

Characteristic

- The machine adopts computer control, CCD photoelectric tracking and correction system, and the winding tension control is realized by the variable frequency vector motor through the PLC touch screen to realize automatic tension control.

- The unwinding tension is controlled by pneumatic brakes (with the Japanese SMC pneumatic proportional valve) and automatic tension control. The take-up reel uses an air expansion shaft.

- The inverter controls the working speed of the whole machine, equipped with automatic meter counting device, automatic winding calculation and display, unwinding setting, automatic shutdown and other functions.

- The utility model has the advantages that the slit is smooth, the winding end surface is neat, and the subsequent processing is facilitated.

Main Technical Parameter

| No. | Item | details | unit |

| 1 | Suitable material | Self-adhesive/BOPP/CPP/PET/PE/soft aluminum composite film/aluminized film and other roll-shaped materials. | |

| 2 | Thickness range | 0.012-0.15 | mm |

| 3 | Effective width | 1600 | mm |

| 4 | Roller width | 1650 | mm |

| 5 | Unwinding diameter | 800(Max) | mm |

| 6 | Winding diameter | 600(Max) | mm |

| 7 | Working speed | 500 | M/min |

| 8 | Tension range | 30-300 | n |

| 9 | Unwinding tension control | Constant tension by load cell | |

| 10 | Winding tension control | Taper tension | |

| 11 | Edge position correction | ||

| 12 | EPC precision | ±0.3 | mm |

| 13 | EPC working space | ±100 | mm |

| 14 | Winding way | Center winding | |

| 15 | Loading way | Shaftless cone, hydraulic lifting and loading | |

| 16 | Unloading way | Side wall type rewinding and unloading, unloading rack auxiliary unloading | |

| 17 | Unwinding paper core | 3inch(76mm)6inch(152mm) | |

| 18 | Winding paper core | 3inch(76mm) | |

| 19 | Slitting width | 80-1600mm | |

| 20 | Meter precision | ±1/1000 | |

| 21 | Unwinding power | 3.7 | kw |

| 22 | Winding power | 3.7kw*2 | |

| 23 | Traction power | 5.5kw | |

| 24 | Edge blowing power | 1.5kw | |

| 25 | Total power | 16kw | |

| 26 | Power supply | 380v,50hz | |

| 27 | Air pressure | 0.6mpa | |

| 28 | Dimension | 2400*3500*2050(L*W*H)MM | |

| 29 | Unload system space | L500*W2000mm | |

| 30 | Weight | 5500kg | |