| Model: ZBJ–N12 Ultrasonic

Paper Cup Machine |

||

| Speed: 100–150 PCS/minute,

Material: One or Two side PE coated paper, Paper: 170~300gsm, Size: 3~16oz, |

||

|

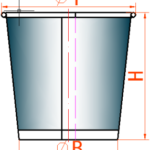

Top: 45~90 mm

Bottom: 48~72 mm Height: 40~127 mm |

|

| Working Power: 15KW,

Power: 50Hz, 380V 3-phase, GW/NW: 2200/2100KG Size: L2350*W1100*H1850 mm |

||

| Model | ZBJ-N12 High Speed Ultrasonic Paper Cup Machine | |

| Paper Cup Size: | 3 ~ 16 oz | |

| Rated Speed: | 100 ~ 150 PCS/minute (on cup size, speed different)

Speed affected by cup size, paper quality & thickness |

|

| Raw Material: | One-side or Two side PE coated paper | |

| Suitable paper weight: | 170~300gsm | |

| Power Source: | 50Hz, (380V 3-phase, 50Hz), (Better use 380V 3-phase)

* if User power different? Please INFO US IN ADVANCE. |

|

| Total Power: | 18.5KW | |

| Working Power: | 15KW (compressor hot air) | |

| Total Weight: | GW/NW: 2200/2100KG | |

| Pack Size (L*W*H) | 2350 x 1100 x 1850 mm | |

| Working Air Source: | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute

User should BUY Air Compressor |

|

| Cup Side Welding: | Ultrasonic | |

| Cup Bottom Heating: | Hot Air (Need Air compressor supply air) | |

| Cup Bottom Knurling: | Heater Knurling (if use single PE coated paper) | |

| Cool Device (circle water), for double PE coated paper | ||

| We Reserve the right to alter specifications without prior notice. | ||

| Main improved:

# Speed 100~150 cup/minute # HMI & PLC Program computer control, easy operate, fault auto-stop and easy solution. # Adopt double Cam ,turntable cam and rotating cup cam, compare with index gear box, easy maintenance, stable and reliable, easy replace broken parts. # Main mechanism and movement control by quality gears and shaft/axis, which is more efficient than chain axis. # Self lubricate (automatic oil lubricate), # Bottom 4 hot air heating ,good sealing. # Quality bearing and electronic element, long life, # Robot straight lift the cup body to main mold. # Step motor control the bottom feed, precision and reliable. # Bottom disk straight punched and send to the cup body, less wastage and precision. # Advanced bottom knurling system, reliable and long life, # Cup side sealing ultrasonic (1PE & 2PE paper), # Working power less, save cost, # With cup collector/stacker, One worker run 2~3 sets cup machine, save labour, # Optimize the movement design, frame, parts, machine more light pressure, long life time. |

||

点击空白处返回

![]()

- Description